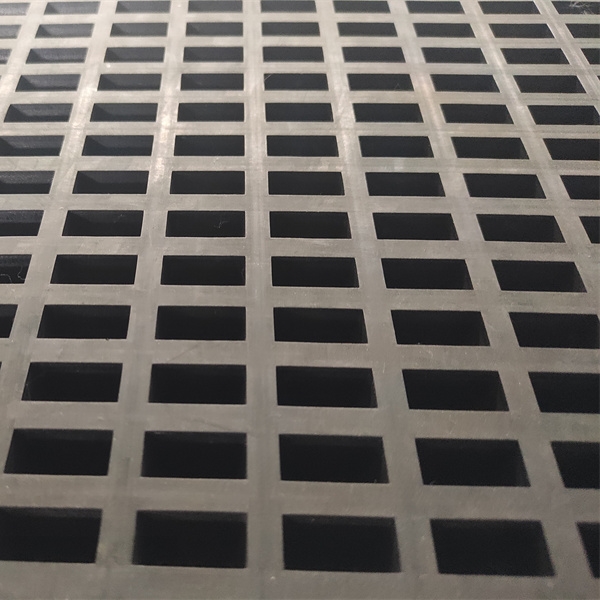

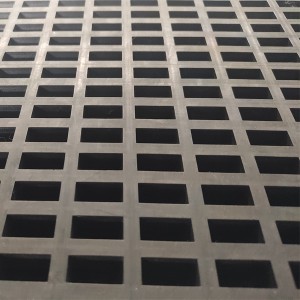

Tsarin allo na roba

Kafofin watsa labaru na allo muhimmiyar iko ne mai mahimmanci na kayan aikin. Lokacin da allon girgiza ke rawar jiki, ta fuskoki daban-daban da masu girma dabam da kuma a ƙarƙashin aikin sojojin waje, za a raba kuma su cimma manufar grading. Duk nau'ikan kaddarorin na kayan, tsari daban-daban da kayan kwamiti da sigogi daban-daban na na'urori iri iri suna da tasiri kan iyawar allo, ingancin aiki da rayuwa. Daban-daban kayan, wurare daban-daban, ya kamata zaɓi samfuran da ke da alamomin yanar gizo daban don cimma sakamako mafi kyau.

Ya dogara da kayan aiki daban-daban, buƙatun da ake buƙata, za a raba kafofin watsa labaru ta jerin ƙasa

1. Memodular jerin

2. Fita jerin

3. Series 3.par

Haɗin da ke da kayan aikin gabaɗaya ya kasu kashi ɗaya: Haɗin Mosawa, haɗin kai, haɗin kai, haɗin kai tsaye, haɗin yana nuna haɗin kai da sauransu.

Aikace-aikacen mining

1.Pre-nika ore

2.Pre- Leach Leach

3.Hiighta ferruous ore

4.Mill sakin fuska

5.Dazarar kafofin kafofin kafofin watsa labarai

6.Control nunawa - kyakkyawan cirewa

Tsarin allo na roba ya zama na musamman a tsarin tsari, ban da amfani da babban yanayin roba mai tsauri a cikin tsarin lalacewar kayan), samfurin ba kawai yana da babban mamaki ba, har ma has a uniform opening. The space rib will never break. Compared to wire screens, which have a lower opening screening area on smaller apertures. An kera matukan ƙirar roba ta babban kayan da ke da ƙarfi, suna da kyau kamar kammala akwatunan allo ko a matsayin sashe. Ana samun waɗannan allo a cikin kewayon murabba'ai ko sloted apertures don dacewa da kowane nau'in buƙatun grading. Amfanin allo na roba shine mai tsayi da kuma rage yawan amo. Allon tashin hankali na roba sun fi dacewa da matsakaici sosai ga aikace-aikacen allo. Yin amfani da roba zai rage amo, rage toshe kuma ka ba da damar sanyawa. Ana kerarre kan tsarin roba na roba na roba ta amfani da yadudduka 2 na ƙwararrun roba mai tsayayya da roba mai tsayayya da roba. Hakanan ana samun masu girma dabam da yanayin aiki akan buƙata.

Jerin allon allo na roba

Tsarin allo na roba

Aiki mai aiki na samfuran allo na roba

| Dukiya | Raka'a | Daraja |

| Ƙanƙanci | Bakin teku a | 63 |

| Da tenerile | MPA | 19 ± 10 |

| Karya elongation | % | 660 ± 10 |

| Ƙarfi ƙara | N / mm | 313 |

| Hasashen Abrasion | % | 37 |

| Matsayi na aiki | -30 ℃ zuwa + 60 ℃ | |

| Launi | Baƙi |

Fasas

1.Hight Shafin Shaida

2.No Project Provinging

3.Long sabis

4.Ol juriya

5.Corroon juriya

6. Juriya ce